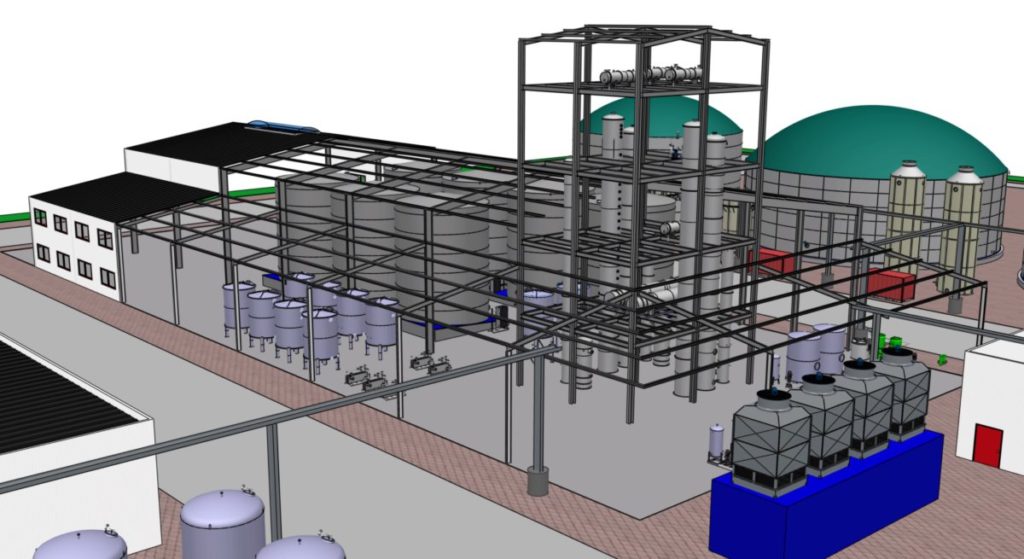

Die Unternehmensgruppe Schmitt bietet ihren Kunden energiesparende, kundenspezifisch angepasste und schlüsselfertige Bioethanolanlagen an.

Neben hochwertigem Bioethanol entsteht als Nebenprodukt außerdem dabei die sogenannte Schlempe. Diese wird aus dem Sumpf der Destillationskolonne abgeführt, und anschließend zu hochwertigem Viehfutter in frischer oder getrockneter, beständiger Form (DDGS), weiterverarbeitet.

It is also possible to use the stillage as substrate for biogas plants.

Process

Getreidekörner werden nass vermahlen, mit Wasser und Amylase-Enzymen vermengt und zur Verzuckerung der Stärke erhitzt. Der sogenannten Maische wird Hefe zur alkoholischen Vergärung des Zuckers zugesetzt. Danach wird Ethanol wird von der vergorenen Maische mittels Destillation getrennt. Das Ethanol-Wasser Gemisch wird dann durch Dehydrierung weiter zu entwässertem Ethanol verarbeitet.

By-products:

• Biogas > Dampferzeugung für die Brennerei, Betreiben eines BHKW

• Strom > aus eigenem BHKW zum Eigenverbrauch und Einspeisung

• Stickstoff-Dünger > gezielte Düngung der umliegenden landwirtschaftlichen Flächen

• Abwärme > Beheizung von Apparaten in der Produktion, Hallenheizung im Winter

Recent Comments